Horizontal vs. Vertical Centrifugal Casting: What’s the Difference?

Key Takeaways

- Horizontal centrifugal casting is ideal for long, cylindrical parts like tubes and sleeves.

- Vertical centrifugal casting is better suited for short shapes with large wall sections such as flanges.

- Each method affects wall thickness, metal flow, and final part performance

- Orientation choice depends on part geometry, specifications, and application needs

Centrifugal casting is a preferred method for producing high-integrity metal components, especially in industries where strength, reliability, and dimensional accuracy are non-negotiable. From petrochemical to aerospace and power generation, this process helps ensure long service life even in extreme operating environments. But the choice between horizontal centrifugal casting and vertical centrifugal casting can significantly influence a part’s quality, performance, and cost-effectiveness.

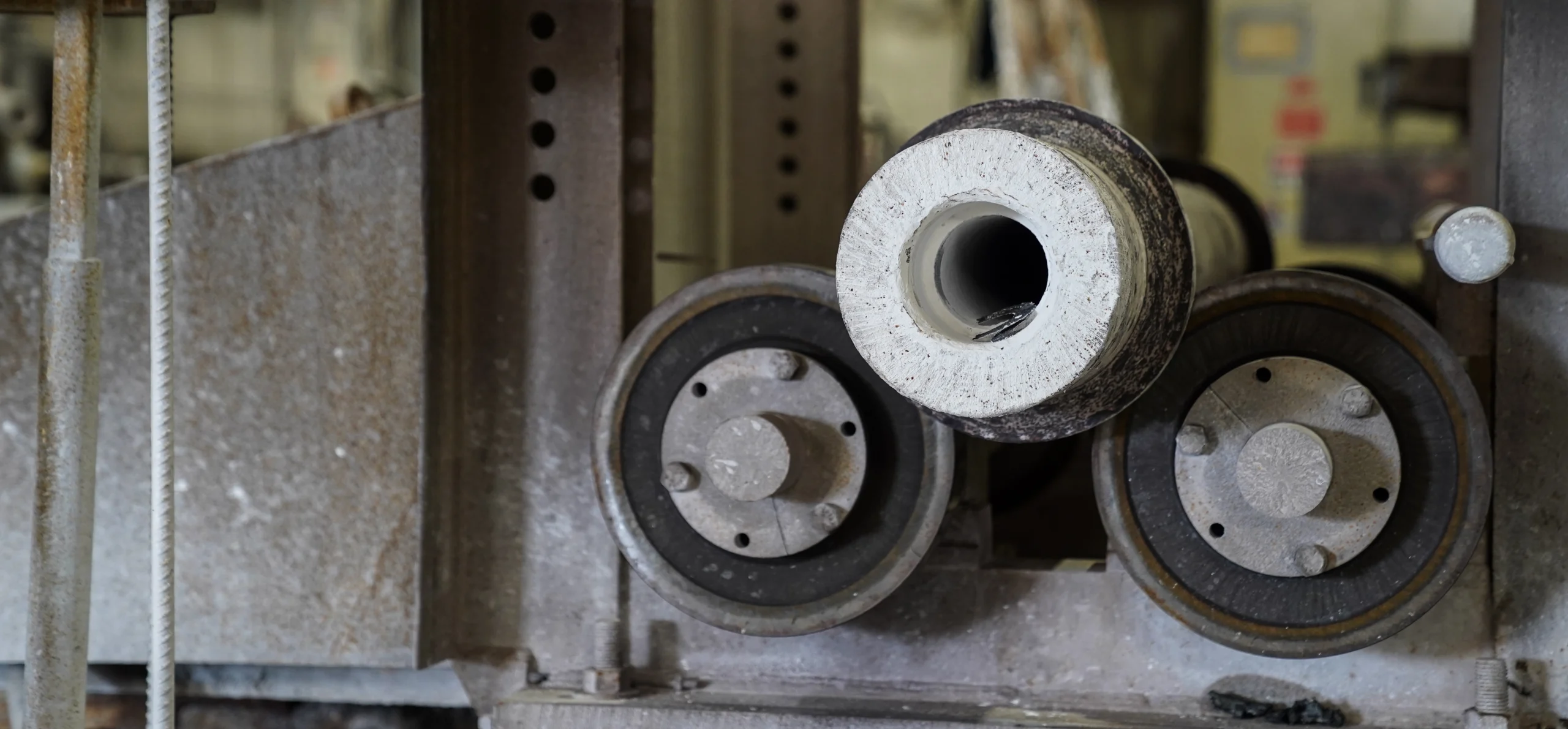

Horizontal Centrifugal Casting

This method uses a mold that spins on a horizontal axis and is best suited for relatively smaller wall sections like tubes, liners, and sleeves. As molten metal is poured, centrifugal force distributes it evenly against the mold wall. Impurities and inclusions are forced inward, creating a dense outer shell that’s later machined to drawing and tested per specification. This process is ideal for applications involving wear, pressure, or high-velocity fluids—such as pump sleeves or heat exchanger tubes. Certain alloys also respond better to horizontal casting due to the way they solidify along the mold length.

Vertical Centrifugal Casting

In vertical casting, the mold spins on a vertical axis, making it ideal for flanges, and other shapes that require thick wall sections. It is also possible to cast some asymmetrical shapes utilizing vertical centrifugal casting.

Why It Matters

Choosing the wrong casting orientation can compromise performance, increase machining costs, or reduce lifespan. The right method ensures better metallurgical properties, dimensional consistency, and long-term value.

The Delta Centrifugal® Advantage

Delta Centrifugal® specializes in horizontal centrifugal casting. We focus exclusively on this manufacturing method because it offers the greatest range of solutions for our customers, without compromising our unwavering commitment to quality. Our unmatched technical capabilities, alloy expertise, and advanced equipment ensure your castings are engineered for precision and built to perform.

Horizontal vs. Vertical Centrifugal Casting: What’s the Difference?

Key Takeaways Horizontal centrifugal casting is ideal for long, cylindrical parts like tubes and sle

Martensitic Stainless Steel Casting

Why it Matters and How Delta Centrifugal® Leads the Way Martensitic stainless-steel casting offers

Centrifugal Casting Material Equivalents

The alloy manufacturing industry is a very diverse one, encompassing dozens of manufacturing methods